Introducing VersaTrax™, the (not-so-new) leader in advanced robotic solutions revolutionizing inspection, non-destructive testing (NDT), and remote tooling operations. VersaTrax offers a comprehensive series of versatile inspection crawlers meticulously designed for a wide range of applications, from NDT techniques to remote industrial tasks. With precision and adaptability at its core, VersaTrax empowers seamless inspections and maintenance in the most challenging environments, including confined spaces. Integrated with state-of-the-art technologies, VersaTrax ensures unparalleled efficiency, safety, and accurate results in every mission. Faced with confined space entry, limited access points, or potentially dangerous environments? VersaTrax it!

Select your application or contact us to discuss your unique requirements.

Details

Keep Operations On Track with VersaTrax

Meet the VersaTrax Lineup

Explore our diverse lineup of inspection crawlers, each designed to meet your precise requirements:

- VersaTrax I-Series: Ideal for confined spaces, these miniature pipe inspection robots feature inline tracks powered by gravity or mechanical traction enhancements.

- VersaTrax P-Series: High-tech robots designed for long-distance inspections (up to 1 km/0.6 mi) with a wide parallel chassis and gravity-based traction.

- VersaTrax Y-Series: A robust solution for evaluating hard-to-reach areas, featuring a Y-shaped chassis that maximizes adhesion to internal pipe surfaces.

- VersaTrax M-Series: High-definition robots built for exploring tight spaces within ferrous assets, ensuring strong magnetic adhesion to steel structures.

- VersaTrax NDT: Field-proven robotic solutions tailored for non-destructive testing, enabling mobility in challenging confined spaces.

- VersaTrax OnSpec: Custom robotic inspection solutions designed for unique conditions, technology integration, and complete crawler customization.

I See: Universal Control and Operations with ICON Software

ICON™ software is the versatile and adaptable control and operations software for Eddyfi Technologies cameras and crawlers. Designed with a multi-mission modular approach, ICON provides a universal platform for all micro-controlled standard products and custom robotic solutions, ensuring a common control interface across systems. Users can choose their preferred control method, whether it's a keyboard, mouse, touchscreen, or even an Xbox controller. The software allows for video recording, snapshot capture, and tagging of areas of concern, with remote sensor data collected alongside remote visual inspection (RVI) video. ICON tailors its functionality to meet specific inspection needs. It also supports job management, video and snapshot recording, instrument panel customization, user access management, automation rules, and seamless sensor integration. Whether navigating challenging environments or handling multiple systems, ICON ensures a streamlined and intuitive user experience.

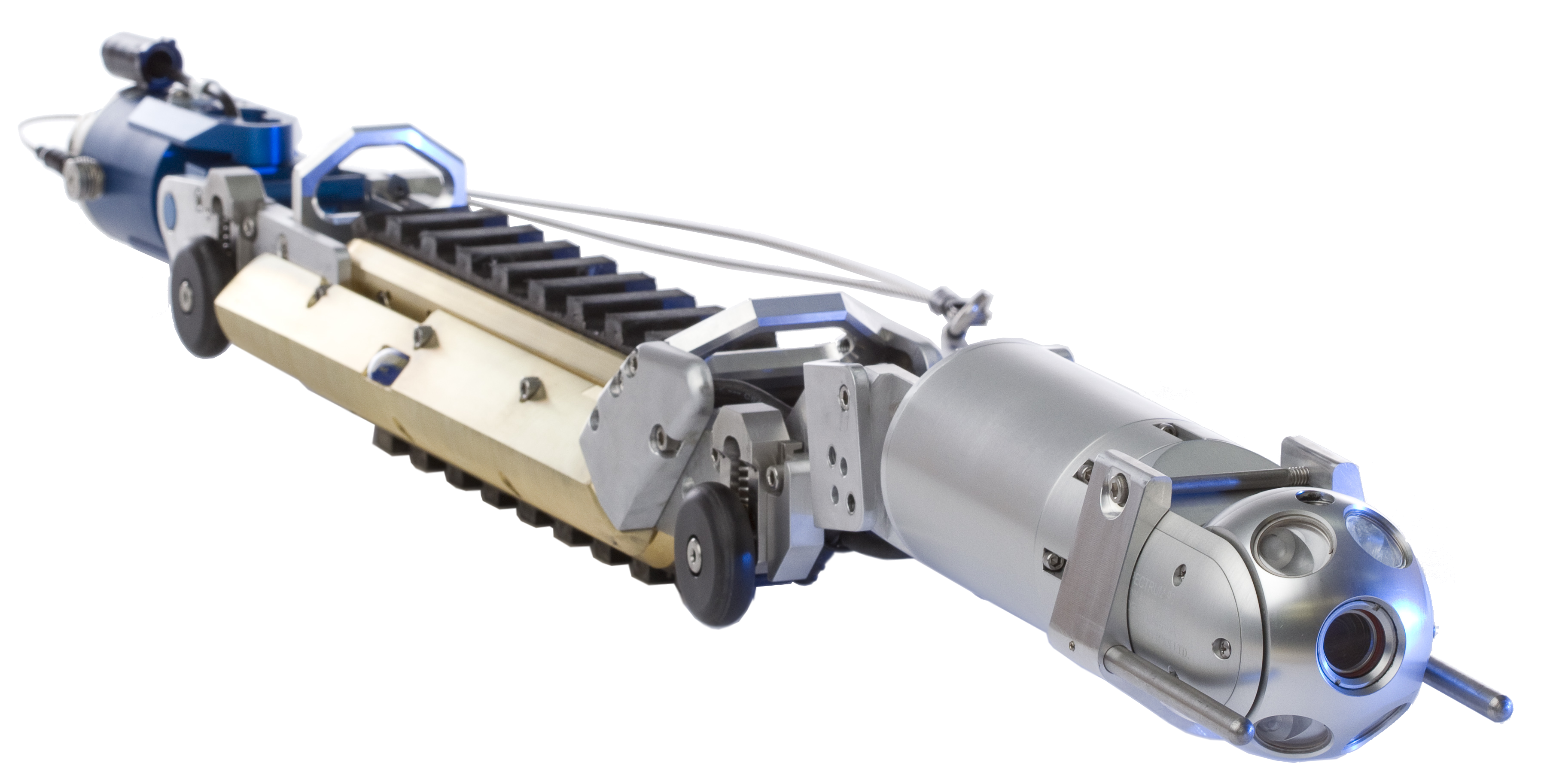

I-Series: Unmatched Performance. Extra Small Form Factor

Introducing VersaTrax I, the ultimate miniature pipe inspection crawler. It excels in tight spaces and tough environments, providing exceptional flexibility. The I-Series sets a new standard for pipe inspection. Thanks to its inline track design, these VersaTrax robots can reach areas that were previously inaccessible, making them perfect for inspecting small to medium-sized pipes, tanks, boreholes, and cramped spaces that require downhole cameras. You can see how it was used for inspecting double-shell tanks at the Hanford site here.

Eddyfi Technologies' robotic crawlers are ideal for inspections in various industrial settings, from petrochemical plants to refineries. If you need to perform remote visual inspections in confined spaces with limited access, the I-Series is a must-have addition to your NDT toolkit.

VersaTrax I-Series crawlers come equipped with durable inspection cameras designed to withstand harsh industrial conditions. They offer ultra-low latency video streaming, allowing operators to navigate obstacles and make quick decisions, even from distances of up to 1 kilometer (0.6 miles) away. Camera options range from fixed focus to full pan, tilt, and zoom (PTZ). Experience the VersaTrax I-Series difference - it's more than just a crawler; it's a versatile solution that redefines what's possible in confined space and pipe inspections.

Ask an Expert

VT-I50, small class crawler, perfect for RVI and NDT in small diameter pipes.

VT-I100, medium class crawler, designed for RVI and NDT in small diameter pipes.

VT-I150, large class crawler, ideal for long-range FOSAR, NDT, and cleaning in small diameter pipes.

P-Series: Best in Class. Far...and Away

The VersaTrax P is an advanced robotic crawler designed for long-distance pipe inspections. With its wide parallel stance and gravity-based traction, this state-of-the-art system can travel up to one kilometer (3,300 ft) in a single run. Versatile and adaptable, it excels in inspecting various industries, including sewer and freshwater lines, hydroelectric penstocks, petrochemical pipelines, and more. Equipped with features like a motorized camera raise function, high-definition camera options, waterproof capabilities up to 60m/200ft, and intuitive controls, the VersaTrax P-Series offers comprehensive remote visual inspections while accommodating specific job requirements. Its exceptional long-distance inspection capabilities make it an ideal choice for confined spaces, hazardous environments, and underwater applications, setting it apart as a reliable solution. Hear firsthand on how this crawler is deployed for efficient internal pipeline inspections here.

The VersaTrax P doesn't just meet industry norms; it surpasses them by operating in pipes as small as 205mm/8in and covering distances of up to 1,000m/3,300ft in one go, with extended options available. It even offers a fiber optic cable option for high-bandwidth payloads, ensuring detailed structural integrity assessments. With Eddyfi Technologies' commitment to innovation and adaptability, the VersaTrax P-Series stands out as a tireless workhorse ready to transport specified payloads and deliver exceptional inspection results, setting a new standard for remote visual inspections.

Ask an Expert

VT-P205, medium class crawler, specialized for internal pipe inspections.

VT-P320, large class crawler, designed for sewer pipe inspections, penstock inspections, and tunnel applications.

Y-Series: Up. Down. See All Around

The VersaTrax Y stands as a game-changing inspection robotic solution, tackling the most challenging industrial scenarios. With its innovative Y-shaped crawler chassis, this system harnesses expansion forces to deftly navigate unpiggable pipelines, adapt to varying pipe diameters, and negotiate bends, regardless of orientation—be it vertical, horizontal, or anything in between. Unlike traditional magnetic-based systems, the Y-Series relies on expansion forces instead of magnets, making it the go-to choice for inspecting non-ferrous assets. Equipped with a rear-facing camera, independent track control, and auxiliary LED lighting, operators can perform comprehensive remote visual inspections, even in submerged conditions, with waterproof capabilities up to 60 meters (200 feet). This versatile robot is an indispensable tool for assessing the integrity of flexible risers, pipelines, refineries, and a wide range of non-ferrous infrastructure, providing a reliable and efficient solution for the most inaccessible industrial locations. See a great example of a marsupial setup employing the VersaTrax Y for transporting tools used for pontoon tank inspection here.

VT-Y200, medium class crawler designed for vertical piping, multi-bend/multi-diameter piping, cleaning, internal NDT in pipes, and marsupial operations.

VT-Y380, large class crawler suitable for vertical piping, multi-bend/multi-diameter piping, cleaning, internal NDT in pipes, and marsupial operations.

M-Series: See Quality. Experience Value

The VersaTrax M inspection crawler revolutionizes remote visual inspection with its magnetic architecture designed for inspecting ferrous assets. Using magnets, this modular inspection robot adheres to ferrous surfaces, making it perfect for examining steel structures, including above ground storage tanks, pressure vessels, ship hulls, wind turbines, and more. Take a closer look at how this crawler is used in the renewable energy sector here. With a small footprint and accommodating chassis, it provides access to tight spaces and offers real-time recording of live video, still images, and sensor data. The M-Series 310 is ideal for quick, out-of-reach viewing, while the M-Series 460 accommodates various payload requirements. This miniature magnetic crawler can travel distances up to 100m/330ft in air or underwater up to 60m/200ft, access spaces as small as 310mm/12.2in, and even offers optional laser lines for on-screen size estimation. Its intuitive functions make it easy for inspectors to operate, and it can be readily adapted for other NDT sensors and tooling to meet specific job requirements. VersaTrax M sets the standard for efficient, high-definition remote visual inspection.

VT-M310, medium class crawler, designed for tank inspections, vessel inspections, wind tower inspections, and weld inspections.

VT-M460, large class crawler, suitable for tank cleaning, offshore pylon inspections, and ship hull inspections [shown with options].

NDT: Taking Advanced Inspections to the Next Level

Introducing VersaTrax NDT inspection crawlers by Eddyfi Technologies: a game-changer for critical component inspections in tough spaces, boosting safety for inspectors. With a flexible modular design, VersaTrax NDT accommodates various non-destructive testing techniques like ultrasonic testing (UT), eddy current testing (ECT), alternating current field measurement (ACFM®), and general visual inspection. These tether-based robotic systems offer frequent in-service asset integrity assessments, real-time condition insights, and access to confined or hazardous areas for data collection. They eliminate the need for scaffolding, rope access, confined space entry, and asset downtime. VersaTrax NDT is a must-have for advanced non-destructive testing inspections in once-inaccessible spots.

Remote Wall Thickness Measurements with Ultrasonic Testing

Harnessing the power of VersaTrax to extend ultrasonic testing technology reach, Eddyfi Technologies’ R-Scan package allows for the collection of UT wall thickness measurements up to a distance of 30m (100ft). UT thickness measurements are collected every 1mm (0.04in) and displayed to the operator in real-time as a B-scan, A-scan trace, and thickness measurements. Compared to traditional spot readings, the R-Scan delivers a much higher Probability of Detection (PoD) with a reliable, recorded, and auditable data set and all from a safe location. Designed to be used in remote locations and harsh petrochemical environments, the R-Scan utilizes a unique dry-coupled ultrasonic (UT) wheel probe, eliminating the need for couplant or constant water supply, making it the ideal partner for the VersaTrax NDT. The probe, a dual crystal 5MHz ultrasonic transducer with a unique rolling probe face, can measure material thickness ranging from 2.5mm up to 100mm (0.1in up to 4in). The R-Scan scanning head is fitted with an encoder to provide accurate positioning information during an inspection. Wheels assist when scanning vertically or if inverted by minimizing the possibility of encoder slippage. See how this technology combination was employed for advanced pipeline inspection here.

Made for the field, the Mantis™ is one of the most robust and reliable industrial ultrasonic instruments ever produced by Eddyfi Technologies, thanks to careful consideration of the highly durable materials chosen. Mantis not only offers conventional UT but more advanced PAUT, TOFD and TFM all through its streamlined user interface, Capture™. With three different models, Mantis addresses both general and advanced applications without compromising productivity.

Remote Weld Inspection with Alternating Current Field Measurement

VersaTrax transforms ACFM inspections, granting access to previously inaccessible locations. Renowned for its precision in detecting and sizing surface-breaking cracks through paint and coatings, ACFM's versatility reaches new heights with VersaTrax. The Amigo™ 2 ACFM Instrument, a rugged self-contained unit with an intuitive touchscreen interface, extends inspection capabilities up to 50 meters (164 feet), addressing challenging scenarios. Advanced signal processing and an exceptional signal-to-noise ratio enhance the detectability of small defects even under thicker coatings, ensuring swift, precise asset management decisions. ACFM probes offer accurate defect sizing and data recording, significantly expediting inspections while reducing false calls, saving time and costs. Discover the role of this technology duo enabling more proactive maintenance and repairs of ships here. VersaTrax empowers ACFM inspections in previously unreachable areas, setting a new standard for non-destructive testing in complex geometries and rough welds.

Remote Butt Weld Inspection with Tangential Eddy Current Array

VersaTrax, in conjunction with Sharck BW's Tangential Eddy Current Array (TECA™) technology, revolutionizes butt weld inspections by significantly enhancing efficiency. Sharck BW excels in identifying and characterizing fatigue cracks within butt welds, measuring their dimensions precisely up to a depth of 7mm (0.28in) without the need for paint or coating removal. When combined with the VersaTrax inspection crawler, this solution eliminates the need for complex scaffolding or endangering rope access technicians. Sharck™ probes, featuring 22 spring-loaded ceramic sensors and a 53mm (2.1in) scan width, facilitate comprehensive inspections of flat or curved surfaces, including cap, toe, and heat-affected zones in a single pass. TECA's unique tangential coil positioning and parallel eddy current flow enable superior crack detection. Additionally, the user-friendly Reddy® interface with Magnifi® GO software provides real-time visualizations, intuitive analysis tools, and streamlined reporting, making data interpretation and reporting quick and accessible with minimal training, ultimately expediting the inspection process.

Learn moreOnSpec: For Adapting to Atypical Conditions, Specific Technology Integration, and Full Custom Design of Inspection Crawlers

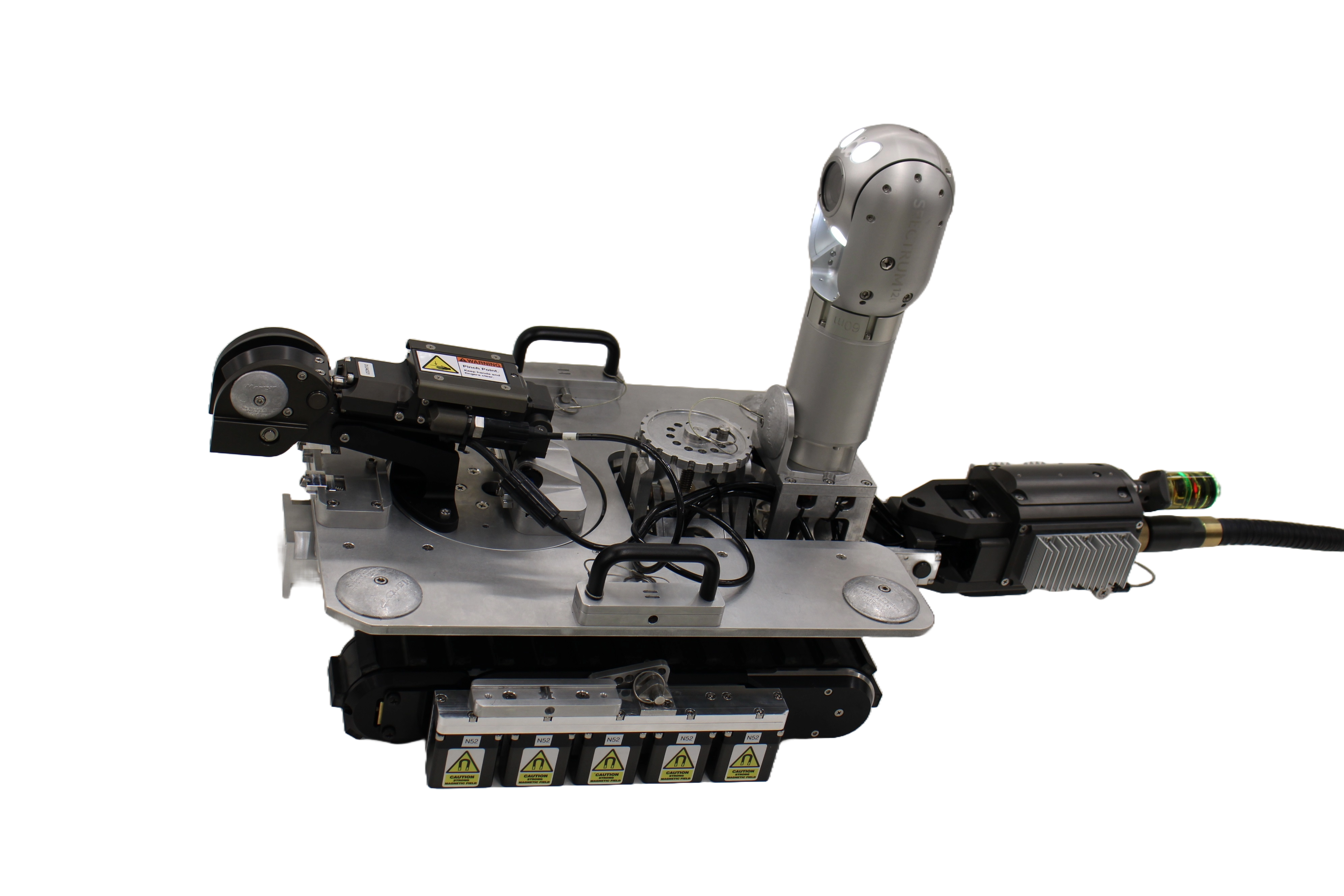

Custom NDT Robotics

Discover tailored NDT robotic solutions with VersaTrax OnSpec. Our OnSpec custom solutions are the answer to atypical inspection challenges. Utilizing universal ICON software across all VersaTrax crawlers ensures an intuitive interface, minimizing training time and boosting productivity. Our OnSpec offerings feature multi-mission modular technology, seamless integration of other technologies, access to confined spaces, and the capability to reach incredible depths. With a dedicated team of design, prototyping, and production experts collaborating in-house, we deliver timely solutions to complex problems.

![]()

At Eddyfi Technologies, we thrive on pushing boundaries and solving industry inspection problems that others won't dare to tackle. Our commitment to bespoke solutions means you deal directly with a vendor willing to listen and create tailored answers for unique challenges. Whether you need off-the-shelf workhorses for routine inspections or heavy-duty, specialized systems for unconventional tasks, we've got you covered 24/7/360°. In today's competitive landscape, gathering precise data is paramount (at great lengths and heights), and our OnSpec solutions provide the specific information necessary for strategic decision-making, especially in the context of aging assets and infrastructure. Trust Eddyfi Technologies to inspect the unexpected and provide the robotic tool you need for remote visual inspection and non-destructive testing.

Beyond Inspection

Eddyfi Technologies stands at the forefront of innovation in industrial robotics, with a renowned reputation for reliability, efficiency, quality, and cost-effectiveness. VersaTrax OnSpec robotic crawlers go beyond inspection, offering custom solutions tailored to your exact needs. These modular, multi-mission robots break the boundaries of human limitations, venturing into perilous or remote environments where direct human intervention is impossible or unsafe. From confined spaces to underwater depths, they seamlessly integrate with other technologies, solving complex technical challenges with agility and precision. Our multidisciplinary team of robotics experts are adept at adapting technology for large-scale facilities and infrastructure. Whether it's maintenance, retrieval, or intricate remote tasks, VersaTrax OnSpec solutions redefine efficiency, safety, and productivity. With a focus on engineering excellence and a commitment to meeting your specific needs, Eddyfi Technologies' robots provide a future-proof, environmentally friendly approach, reducing costs, downtime, and risks across industries like marine transportation, power generation, oil and gas, nuclear, petrochemical, mining, and more. These adaptable robots are revolutionizing remote operations, delivering results that were once deemed beyond human reach. Explore the limitless possibilities with Eddyfi Technologies and VersaTrax OnSpec—your key to a safer, more efficient, and environmentally responsible industrial future.

We believe focused, data-driven dialog is just what will keep us solidly 'on track' together. Eddyfi Technologies is here to provide you with more information, answer any questions you may have, and create an effective solution for your remote-controlled industrial operation requirements.

Ask an ExpertExclusive Content

VersaTrax: A Multi-Mission Modular Approach To Taking NDT Inspections Further

Truly versatile, Eddyfi Technologies’ inspection crawlers are enabling access to non-destructive testing applications in previously in accessible or unsafe environments. See how our plug-and-play robots, powered by a universal software, are keeping operators Beyond Current.

Specifications

I-Series

VT-I50: 50-102mm (2-4in)

VT-I100: 100-150mm (4-6in)

VT-I150: 150-318mm (5.9-12.5in)

VT-I50: 100m (330ft)***

VT-I100: 300m (1,000ft)

VT-I150: 1,000m (3,300ft)

VT-I50: 1.9m (6.1ft) per minute

VT-I100: 9m (30ft) per minute

VT-I150: 6.4m (20.9ft) per minute

VT-I50: 1.1kg (2.5lb)

VT-I100: 5kg (11lb)

VT-I150: 45kg (100lb)

VT-I50: Onyx camera and rear auxiliary camera, Spectrum 45 PT camera optional*

VT-I100: Spectrum 45 PT camera and rear auxiliary camera

VT-I150: Spectrum 90 PTZ camera and rear auxiliary camera, Spectrum 120 HD PTZ camera and rear auxiliary camera optional

VT-I50: IC100 or IC500

VT-I100: IC100 or IC500

VT-I150: IC500

VT-I50: LED camera lighting

VT-I100: LED camera lighting

VT-I150: LED camera lighting

VT-I50: 60m (200ft)

VT-I100: 60m (200ft)

VT-I150: 60m (200ft)

VT-I50: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F)

VT-I100: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

VT-I150: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

Spectrum 45 camera requires the three tracks configuration and will reduce the effective operating range to 75-100mm (3-4in)

Running outside the normal operating condition for prolonged periods of time can affect system performance and reduce life expectancy of some components.

Max tether length requires the three track configuration

P-Series

VT-P205: 205mm (8in)

VT-P320: 320mm (12.5in)

VT-P205: 300m (1,000ft)

VT-P320: 1,000m (3,300ft)

VT-P205:9m (30ft) per minute

VT-P320: 6.4m (21ft) per minute

VT-P205: 8kg (18lb) *

VT-P320: 53kg (116lb) *

VT-P205:6.8kg (15lb)

VT-P320: 45kg (100lb)

VT-P205: 15kg (33lb)

VT-P320: 68kg (150lb)

VT-P205: Spectrum 45 PT camera and rear auxiliary camera

VT-P320: Spectrum 90 PTZ camera and rear auxiliary camera, Spectrum 120 HD PTZ camera and rear auxiliary camera optional

VT-P205: IC100

VT-P320: IC500

VT-P205: 2x auxiliary LED lights

VT-P320: 2x auxiliary LED lights

VT-P205: 60m (200ft)

VT-P320: 60m (200ft)

VT-P205: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

VT-P320: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

Actual pulling capacity is affected by surface condition

Running outside the normal operating condition for prolonged periods of time can affect system performance and reduce life expectancy of some components

Y-Series

VT-Y200: 200-400mm (8-16in)

VT-Y380: 380-915mm (15-36in)

VT-Y200: 300m (1,000ft)

VT-Y380: 1,000m (3,300ft)

VT-Y200: 3.6m (12ft) per minute

VT-Y380: 6.4m (21ft) per minute

VT-Y200: 8.5kg (19lb)

VT-Y380: 46kg (102lb)

VT-Y200: 0.101kg/m (0.068lb/ft)

VT-Y380: 0.119kg/m (0.08lb/ft)

VT-Y200: 17kg (38lb) *

VT-Y380: 34kg (75lb) *

VT-Y200: Spectrum 45 PT camera and rear auxiliary camera

VT-Y380: Spectrum 90 PTZ camera and rear auxiliary camera, Spectrum 120 HD PTZ camera and rear auxiliary camera optional

VT-Y200: IC500

VT-Y380: Rackmount

VT-Y200: 2x auxiliary LED lights

VT-Y380: 3x auxiliary LED lights

VT-Y200: 60m (200ft)

VT-Y380: 60m (200ft)

VT-Y200: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

VT-Y380: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

Actual payload is affected by surface condition, geometry of the pipe (diameter) and bend

Running outside the normal operating condition for prolonged periods of time can affect system performance and reduce life expectancy of some components

M-Series

VT-M310: 310mm (12.2in)

VT-M460:480mm (18.9in)

VT-M310: 100m (330ft)

VT-M460: 1,000m (3,300ft)

VT-M310: 3.6m (12ft) per minute

VT-M460: 6.4m (21ft) per minute

VT-M310: 6.2kg (14lb)

VT-M460: 36kg (80lb)

VT-M310: 0.092kg/m (0.062lb/ft)

VT-M460: 0.119kg/m (0.08lb/ft)

VT-M310: 14kg (31lb)

VT-M460: 24kg (53lb)

VT-M310: HD camera, 120x zoom (10x optical), tilting head

VT-M460: Spectrum 120 HD PTZ camera

VT-M310: IC100

VT-M460: Rackmount

VT-M310: 2x auxiliary LED lights

VT-M460: 2x auxiliary LED lights

VT-M310: 60m (200ft)

VT-M460: 60m (200ft)

VT-M310: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

VT-M460: Normal: 0° to 45°C (32° to 113°F), Limited: -10° to 45°C (14° to 113°F) * *

Actual payload is affected by surface condition and magnetic property of the surface

Running outside the normal operating condition for prolonged periods of time can affect system performance and reduce life expectancy of some components

Download

- VersaTrax I-Series Technical Specifications

- VersaTrax P-Series Technical Specifications

- VersaTrax Y-Series Technical Specifications

- VersaTrax M-Series Technical Specifications

- VersaTrax NDT Technical Specifications

- VersaTrax I50 - User Manual

- VersaTrax I100 and P205 - User Manual

- VersaTrax I150 and P320 - User Manual

- VersaTrax Y380 - User Manual

- VersaTrax M310 - User Manual

- VersaTrax M480 - User Manual